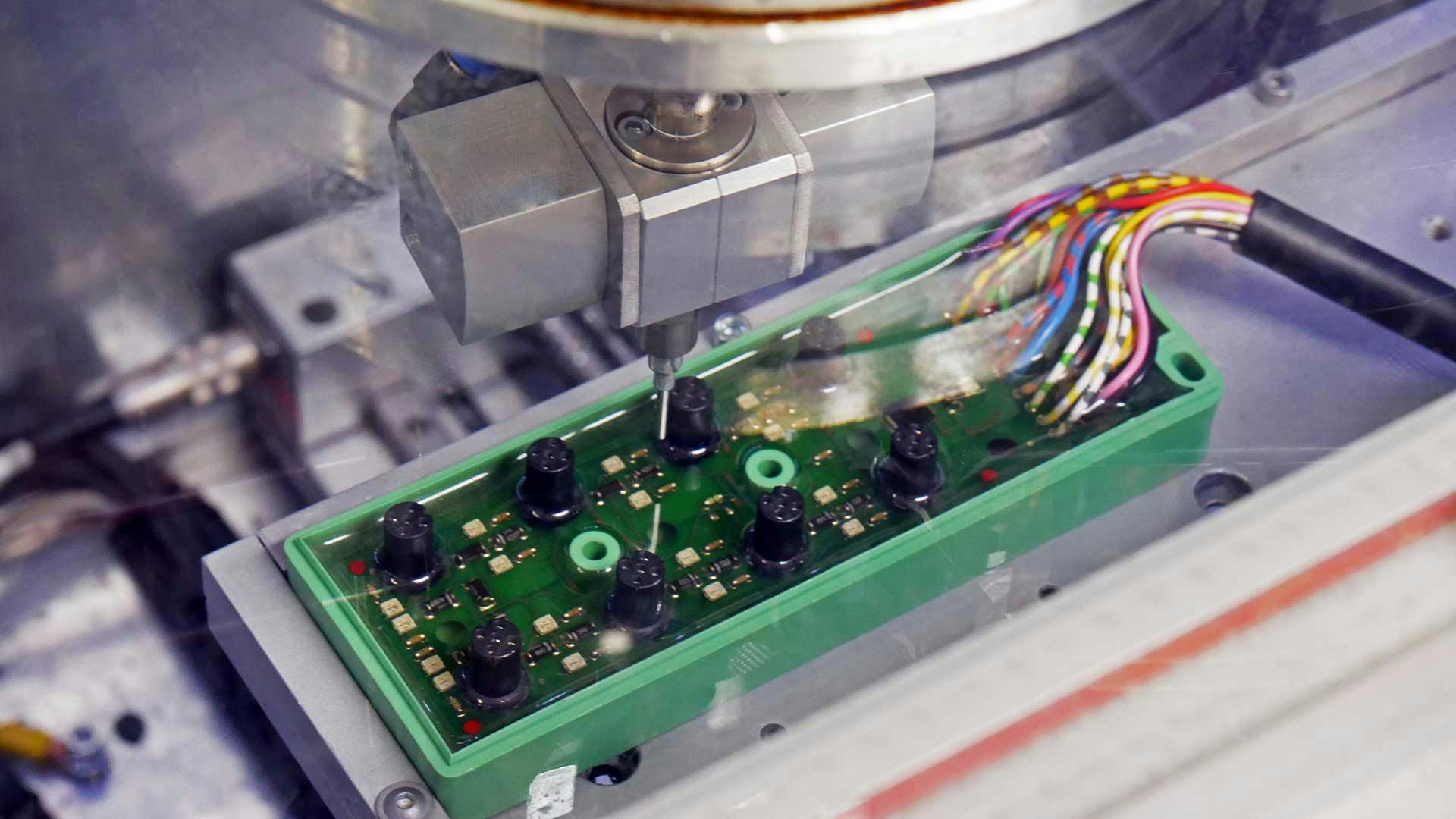

The potting of components is chosen to protect sensitive components, eliminate dust, temperature-related influences, moisture or increase service life. The encapsulation of electronics is also one of the applications of this dispensing process. Components are filled or poured with low-viscosity potting materials such as polyurethanes (PU), epoxy resins (epoxy), silicones.

The material preparation should be selected ideally for the potting medium and according to the application. The reaction casting resin is filled directly into the product through a dispensing head (1K, static, dynamic). Subsequently, curing takes place via time, temperature, UV or humidity.

Typical applications are pacemakers, cable bushings, sensors or electronic components.